Four Tips on Stainless Steel Laser Cutting With The Aid Of 10000W+ Fiber Laser

Four Tips on Stainless Steel Laser Cutting with the aid of 10000W+ Fiber Laser

According to Technavio, the international fiber laser market is anticipated to develop with the aid of US$9.92 billion in 2021-2025, with an annual increase fee of about 12% for the duration of the forecast period. The using elements encompass the growing market demand for high-power fiber lasers, and "10,000 watts" has come to be one of the warm spots in the laser enterprise in current years.

In line with market improvement and person needs, YIDA Laserhas successively launched 12,000 watts, 15,000watts, 20,000 watts, and 30,000 watts of fiber laser cutting machines. Users additionally stumble upon some operational difficulties all through use. We have accumulated and sorted out some frequent issues and consulted slicing engineers to provide solutions.

In this issue, let's speak about stainless metal cutting first. Due to its exquisite corrosion resistance, formability, compatibility, and longevity in a extensive temperature range, stainless metal is broadly used in heavy industry, mild industry, every day requirements industry, constructing decoration, and different industries.

YIDA Laser over 10,000 Watt Laser Stainless Steel Cutting

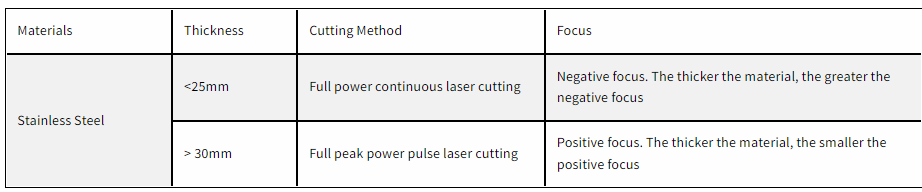

Materials Thickness Cutting Method Focus

Debug Method

Step1. For exclusive strength BWT fiber lasers, refer to the Golden Laser slicing method parameter table, and alter the stainless steel cutting sections of specific thicknesses to acquire the first-class results;

Step2. After the slicing area impact and cutting velocity meet the requirements, modify the perforation method parameters;

Step3. After the cutting impact and perforation procedure meet the requirements, batch trial cutting is carried out to affirm the consistency and steadiness of the process.

Precautions

Nozzle Selection: The thicker the stainless metal thickness, the large the nozzle diameter is, and the greater the cutting air strain is set.

Frequency Debugging: When nitrogen slicing stainless metal thick plate, the frequency is normally between 550Hz and 150Hz. The optimum adjustment of frequency can enhance the roughness of the slicing section.

Duty Cycle Debugging: Optimize the responsibility cycle with the aid of 50%-70%, which can enhance the yellowing and delamination of the cutting section.

Focus Selection: When nitrogen gasoline cuts stainless steel, the high-quality center of attention or poor center of attention ought to be decided in accordance to the fabric thickness, nozzle type, and cutting section. Usually, terrible defocus is appropriate for non-stop medium and skinny plate cutting, and high-quality defocus is appropriate for thick plate pulse mode cutting besides layered area effect.